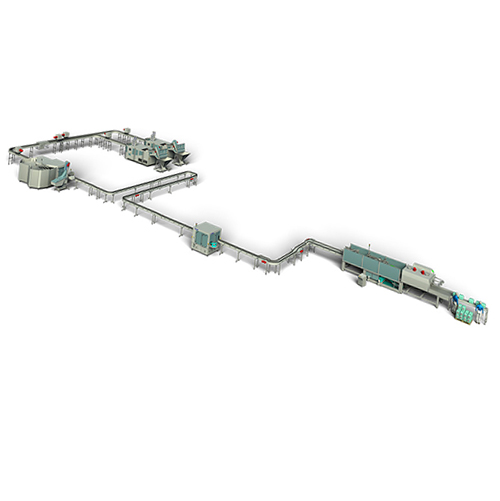

Thông tin chi tiết

Thông số kỹ thuật

Ứng dụng

Thông tin chi tiết

1. Automatic Empty Can De-Palletizer

Equipment Description:

This machine is a auto De-Palletizer. Its function is to unload the stack of aluminum cans produced by the can-making factory from the pallets in units of each layer, and automatically transfer them to other equipment in the filling production line. Automatic loading, lifting, suction cardboard, push cans.

| Technical Parameter | Supplier's Reply | Technical Spec. |

| Overview (Guaranteed Parameters) | ||

| Equipment Form | Auto. De-Palletizer | |

| Single Machine Production Efficiency | ≥98 % | |

| Nominal Production Capacity | 200CPM | |

| Applicable Can type | 330ML | |

| Equipment Features | ||

| Adjustable foot range | Satisfied | ± 50mm |

| Material | Stainless steel | |

| Operation platform | Stainless steel | |

| Pallet Size | 1420 × 1120 | |

| (according to the size of the can manufacturer) | ||

| Empty Can discharging way | Auto. | |

| Sheet Collection Way | Auto. | |

| Motor Brand | Domestic high quality | |

| PLC | Siemens 1200 | |

| Control Voltage | DC 24V | |

| Working Voltage | AC 380V | |

2. Auto Empty Can Rinser

Equipment Introduction:

Empty can transported to the front-end flip, can neck will be flipped down, then rushed into the can rinser, empty can translation along tilting mechanism scroll from top to bottom, from the empty cans into the rinser starts, the rinsing tube with water pressure will rinse the inside of empty cans.

| No. | Item | Parameter |

| 1 | Capacity | 200 CPM |

| 2 | Working pressure | 0.2-0.4Mpa |

| 3 | Water consumption | 1.5M3/h |

| 4 | Weight | 287Kg |

3. Auto Beer Can Filler+Seamer

Main Technical Features

– Filling and seaming is unity designed and filling drive system is supplied by sealing system to make sure both absolutely synchronous and coordinate.

– Frequency control of production speed

– Counter-pressure filling is applied which owns the advantages of high speed, accurate liquid level, low beer lost, good seaming quality.

– Filling volume control type of can is vent tube control—accurate liquid level.

– For empty can, there is CO2 Pre-purging and CO2 Purging, which efficiently decrease the dissolved oxygen.

– During filling process, cans don’t lift while filling valves do. Valve’s lift is controlled by cylinder but not ordinary mechanical type lifting, so there is little wear parts.

– Perfect liquid level control guarantee the stable liquid level inside of filling bowl.

– Seaming technology from FERRUM is used for convenient maintenance.

– Perfect design for CIP channel, convenient to cleaning inner place

CIP Cleaning System

4. Seaming System

5. Tunnel Pasteurizer

| No. | Name | Parameter |

| 1 | Equipment type | Single-Layer Tunnel Pasteurizer |

| 2 | Reliability | ≥98% |

| 3 | Effective Treatment Area | 22M2 |

| 4 | PID regulation range | 10-25PU (adjustable) |

| 5 | PU control range | ±2PU |

| 6 | Pasteurizing Temperature Error Range | ±0.5â |

| 7 | Total working time | 30Min |

| 8 | Heating time | 18Min |

6. Can Dryer

7. Auto Carton Packer

Thông số kỹ thuật

Ứng dụng

khách hàng của chúng tôi

Trong suốt thời gian hình thành & phát triển, Cao Việt Mỹ rất vinh hạnh khi được nhiều khách hàng tin tưởng chọn lựa và gắn bó lâu dài. Chúng tôi luôn tự hào là đơn vị được sự tín nhiệm cao của nhiều quý khách hàng.

.jpg)

.jpg)