Thông tin chi tiết

Thông số kỹ thuật

Ứng dụng

Thông tin chi tiết

Features

Each food machine is controlled by PLC, making each process convenient to operate.

Produced filling cakes can be arranged in the trays with two arranging modes. They are in parallel arrangement and cross arrangement, meeting requirements from different customers.

All parts coming into contact with food adopt 304 stainless steel and food grade plastics to ensure the food safety and hygienic.

The control system has its own memory function to memorize parameters of different products. During the production, the parameters can be directly used without re-setting, saving time.

We can customize the tray arranging machines following customer requirements (customers should supply the baking tray sizes). This avoids trays replacing in large quantities after purchasing the equipment.

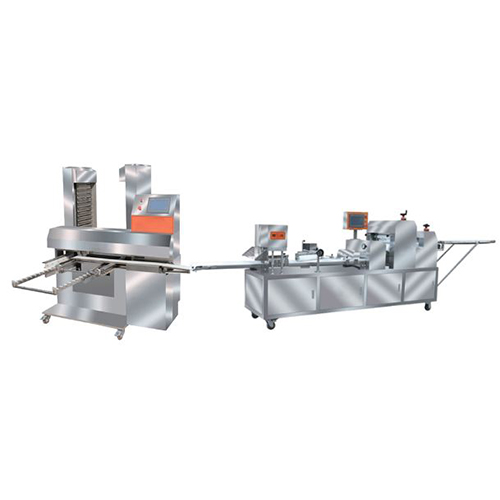

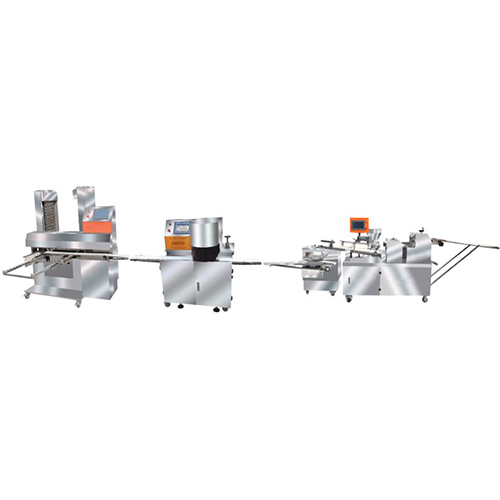

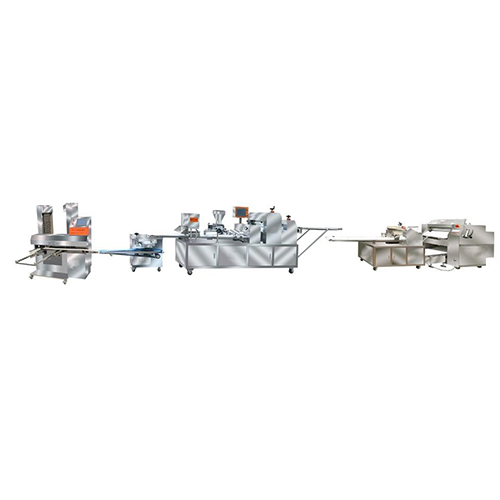

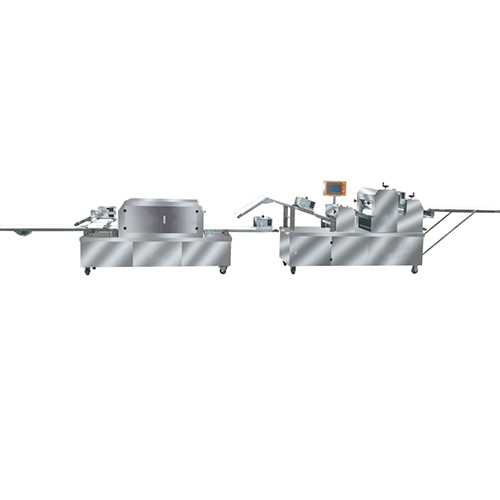

Processing line details display

Feed filling through the stuffing hopper and put dough wrappers form the other side. If you are filling stuffings into your cakes, the middle hopper is used to feed another stuffing.

Stuffing filling.

To be rounded with moon cake forming machine.

Mold can be replaced via moon cake forming machine to obtain the shape and pattern you want. (the mold can be customized)

Enters tray arranging machine through conveying belt.

Tray arranging

Technical Parameters

| Overall size (L x W x H) | 4100x890x1700mm |

| Output | 1000-6000 pcs/h |

| Equipment power | 4.8kw |

| Equipment weight | 1150kg |

| Equipment voltage | 220/380V |

| Finished product weight | 10-300g/pc (special size can be customized) |

| Equipment frequency | 50HZ/60HZ |

| Ratio of wrapper and stuffing | adjustable |

Thông số kỹ thuật

Ứng dụng

Related products

khách hàng của chúng tôi

Trong suốt thời gian hình thành & phát triển, Cao Việt Mỹ rất vinh hạnh khi được nhiều khách hàng tin tưởng chọn lựa và gắn bó lâu dài. Chúng tôi luôn tự hào là đơn vị được sự tín nhiệm cao của nhiều quý khách hàng.